Let me get this off my chest right now. I really dislike how Sarissa identifies their Heroic Old West buildings on their website. I can deal with the Small Option (1-5) and Small Option Plus (1-5) because there are at least pictures to look at. Once you move beyond the small buildings though you are stuck. I can guess that the Medium Option (1-5) at least match up with their small option counterparts. Medium Option Plus (1-5) has pictures (which I suppose might match up with the regular Medium Option buildings). There are no pictures for the Large Option buildings and there are only three variants available. I'm not even sure which one I bought anymore! That's a somewhat minor quibble when it comes down to it, but the other lines they produce have at least line drawings of the buildings if not pictures of the actually building fully assembled.

I would also like to see more variations in the False Fronts of some of these buildings, they are starting to all look the same and although what is being produced (and this is by all the manufacturers) is the most common there were some other designs. The False Front is the store's advertising billboard and they did want to stick out a bit and grab people's attention.

Enough of that and on to the important stuff. The Large Option kits are 2 story buildings and they are the same length as the medium option. They also feature my favorite design for a 2 story building, to get to the 1st floor to move miniatures around the whole 2nd floor lifts off as a single component. The Knuckleduster buildings work the same way while the Battle-Flag buildings have lift off roofs and removable floors. Gamecraft Miniatures kind of leaves you on your own as you have to buy optional floors and then figure out how you are going to make it all work. Aetherworks is an unknown quantity at this point. They do make a couple of 2 story buildings and it looks like they use the Battle-Flag and Gamecraft style with a removable roof and second floor. From a gaming perspective I feel like being able to remove the entire 2nd story is a superior design.

The build for the Large Option building is still pretty straight forward and there is a set of one page instructions included which is pretty straight forward and does show all of the components in an exploded format. These kits go together pretty fast but spending a little time and making sure that your window and door frames are on straight is usually well worth the effort. In an unusual circumstance I managed to avoid making any mistakes on this one!

I do like to use clamps for darn near anything I can get a clamp on to but there are spots where it is difficult to use clamps. I find the steel block weights I have to be particularly invaluable especially since the can be used to keep everything square as well. I may end up browsing the Micro Mark site again just to see if there is anything that catches my eye that would be handy keeping some of these builds square.

Pictures can explain everything better than I can write so let's take a look at what I built:

Now that I have managed to unpack it without drawing blood. I can start building. I'm pretty much ignoring the instructions at this point and following my own sequence of gluing all the window and door frames to the walls using the picture on the instructions for reference.

|

| You do have to keep track of which floor a piece goes to. This is the first floor front, easy to tell because it has three tabs on the bottom edge. |

|

| And the 1st floor rear. Three tabs on the bottom and two slots on the top. This is where the 2nd floor tabs will fit. |

|

| 2nd Floor front. Tabs from the top of the 1st floor will fit into two of the slots while the 2nd story floor will fit into the other two. |

|

| Working on the 1st Floor Sides. Tabs on the bottom edge |

|

| This is the 2nd Story Back. Two tabs and two slots on the bottom, slots are for the floor. There is one tab on the top edge for the flat roof. |

|

| And the 2nd Story Side. Two slots on the bottom edge. |

From here I went right on into the wall assembly

|

| 1st Story walls glued to the base. You can see the tabs for the 2nd Story on the front and slots for the 2nd Story on the back. |

|

| A quick scale shot of a Black Scorpion Gunfighter. I'll be mounting all the miniatures on bases that are not quite as tall. This should help the Black Scorpion miniatures which are tall blend in better. |

|

| Here you can see how the floor for the 2nd Story slots into the Rear Wall. |

Now its time to test fit the 1st and 2nd stories together.

|

| Looks Good! |

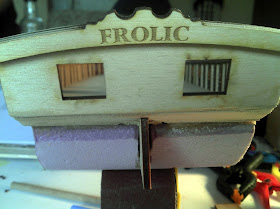

Here is the building with the flat roof that is provided. I went a head and ordered a pitched roof that normally goes on a medium option to see how it might fit.

|

| Just kind of "blah" looking with that flat roof. |

|

| The pitched roof just doesn't cut it. I do wish Sarissa would make a Pitched Roof option for their Large buildings. |

|

| Even worse from the front. Well I have a pitched roof available now when I order a medium building. |

Like with the small option building I really like the sleeker look the 2mm MDF gives you when the building is finished. It is a tied more fragile than the 3mm used by Battle-Flag so be sure you cut out parts rather than trying to push them out from the sprue.

This is a very narrow building, which is good, variety is important when building up a whole town. Here's out it looks against some of the competitions' buildings:

|

| Knuckleduster |

|

| Battle-Flag |

|

| Gamecraft Miniatures |

And then a few more scale shots

|

| Battle-Flag and Black Scorpion |

|

| Small Option and Large Option, Black Scorpion Miniatures |