The Town of Calamity, The D&RGW RR Warehouse Row and Historical Miniature Gaming

Quotes

Wednesday, December 23, 2020

Tuesday, December 22, 2020

World War II Project - STuGs - Basic Camo

There was finally sometime from the rush of the holidays to get some painting in. The STuGs received their basic coat of dunkelgelb followed by the red brown and green patterns. My airbrush work still needs some refinement but it’s getting better. I was able to achieve the mottled look that came from the reference book I was using. I wrapped up the day with a coat of satin varnish so they are ready for decals.

Wednesday, December 16, 2020

Wednesday, December 9, 2020

Monday, December 7, 2020

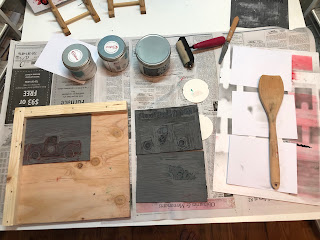

Printing - Its not easy being Green

Printing continues - green is color #2. I should be finishing that today and moving on to the black. I'm dreading the black at the moment since it contains all the lettering. At this point I'm quite pleased with how well the red and green have come together.

|

| I'm sure other printers are cringing at seeing my messy work surface. |

Friday, December 4, 2020

Printing - Red is Finished

Its amazing how much work is involved in a simple design when you start adding colors. First up in the printing process is red. 90 impressions or so,later the red was finished. Messy process but I learned a couple things to make it go a little quicker. You would think that having run a printing press for two years that I would be neater with the ink. I had forgotten how easily ink just gets on everything if you aren't paying attention.

With the red done I can move on to the green.

|

| Everything layed out. The white cards in the corner are proofs. I use those to make sure everything is lining up. There are 5-6 fresh ones just to the right that only have red right now. |

|

| Cards racked and stacked for drying. I don't need the red to completely dry before applying the green, so I'll launch right into that part next. |

Wednesday, December 2, 2020

Monday, November 30, 2020

Printing Begins

Things have gone better than expected with the card. While the image transfer didn't work out quite as well as I had hoped it would, it worked well enough to get the carving done. Next time I need to be sure to cover both surfaces with the gel. I only coated the lino and while that worked the image did pull away with the paper so I need a stronger bond.

All three "plates" are carved and some test prints have been made. The registration of the blocks needs to be adjusted a bit but really it was pretty good considering I really forgot about needing to make registration marks at all.

Here we go ready to start full scale production!

Wednesday, November 25, 2020

Friday, November 20, 2020

Transfer design to block for Linocut

Lo and behold it actually worked! Yesterday I painted the matte gel medium on to the linoleum and put paper copies of the design on top of it. I let that dry overnight. I had hoped to peel it off the top like the one youtube video I watched (although I see that he used glossy gel medium) but it didn't. I then proceeded to Plan B. I simply rubbed the paper off with a damp sponge and it "magically" left the design on the block. Success!

Next step is to start the carving. Each block will be used for a different color; red, green and black and I have a spare if I really screw one of them up. I need to move pretty quickly at this point so that the linocuts are ready when the ink arrives. The ink is arriving from a couple of different sources, it seems there has been quite the run of printers ink across the country during the pandemic.

|

| I cut down the paper to the size of the block after the gel had dried. |

|

| Here the paper is wetted down and I'm rubbing it off gently with a damp sponge. |

|

| And here the image is revealed. I didn't rub the paper all the way off since most of it is going to get cutaway anyway. Time to bring out the blades! |

Thursday, November 19, 2020

Its That Time of the Year - Making Christmas Cards

|

| So many Trees last year |

With everything that has been going on neither my wife or I have felt particularly festive. Yet the holidays are closing in fast and the only thing we have done for the Christmas card is the design (which will not yet be revealed). Suddenly I'm feeling very enthused about it though, so I'm running with it.

|

| Starting the transfer, a piece of linoleum, a cheap brush and Matte Gel |

|

| Spread a relatively thin coating on the linoleum, as thin and even as possible |

|

| Here I'm using the registration marks on the design to get the linoleum in the right spot. Far easier on this small card to place the linoleum on the paper than the other way around. |

Wednesday, November 18, 2020

Monday, November 16, 2020

World War II Project - 70th Tank Battalion Markings

|

| The wording on the sash is 70th in French. The unit's motto is Strike Swiftly. |

As I have mentioned in some earlier posts I have dropped the idea of modeling my M4s as part of the 4th Armored Division. Instead they will be marked up for the 70th Tank Battalion, one of the 60 or so independent tank battalions that supported the infantry divisions.

Initially the 70th was a light tank battalion equipped with M5s. One of its four companies was deployed to Iceland the remainder participated in Operation Torch and fought through the Tunisian campaign. The 70th was assigned to support American, British and French units during this campaign.

Still designated a light tank battalion it participated in Operation Husky the invasion of Sicily. It primarily provided support to the 1st Infantry division for this operation. It was here that the battalion developed a "top down" attack on German armor. The 37mm main gun was not capable of defeating the frontal armor of most German armor. Tankers developed the technique to maneuver to higher ground so they could shoot at the top armor of German tanks.

From Sicily the 70th was pulled back to England and re-equipped as medium tank company with M4s in companies A, B and C with D Company keeping its M5s. It would participate in D-Day supporting the 4th Infantry Division on Utah beach and for most of the rest of the campaign in Europe. On D-Day companies A and B were equipped with M4A1 DD tanks while C Company was equipped with M4s with wading trunks. From here it becomes very interesting from a modeling standpoint.

On D-Day companies A, B & C had red numbers with a white outline while company D had solid white numbers. I have seen the numbers located on the turret (more towards the back of the turret and often on the turret bustle) and the hull side. On the hull side the numbers tend to be either centered on the hull (between the applique armor plates on the right side) or towards the rear of the hull side (just after the applique armor plate on the right). For D company the number was on the hull side, again towards the rear.

Some tanks, perhaps all at this date, had the Joe Peckerwood turtle mascot painted on the hull side more towards the front, often on the front applique armor plates. After this date replacement tanks tended to get solid white numbers and no mascot. From photos various details come to light. Small versions of the tank's number can often be seen on the armor plate that was used to cover the driver's direct vision slot (like A-1, B-12, C-5). The armor group information likewise sometimes appears on the bow gunner's armor plate (70 + hollow triangle). Sometimes this information appears on the lower glacias, sometimes its completely missing.

By the end of the war I have several pictures showing a wide variety of M4s making up the equipment of the 70th; M4A1(75), M4A1(76), M4, M4 Composite, M4A3(75), M4A3(76), M4A3E8, M4A3E2 and my personal favorite the M32B1 ARV. There are versions of these with and without the Summerfield matting that was used to attach camouflage. It really is carte blanche when it comes to modeling the 70th. This would be true of any independent tank battalion they weren't part of a division so they tended to get what ever was available as a replacement. Getting spare parts was hard because of this to the point the maintenance units just said they were with the 70th Tank Division just to get their hands on parts.

There are 1/35th scale decal sets available from both Star and Bison (Its odd but as near as I can tell these two companies are run by the same guy). I'll use those for reference. Company B has a small sheet of 1/56th scale decals but it only includes white stars, the red numbers, the Joe Peckerwood mascot decals and a pair of registration numbers. On top of that its listed, rather generically, as Sherman D-Day Markings. I'm musing on having a custom set of decals made, but I sometimes have problems with their decals which makes me leary of a custom set. Things to ponder, I still have STuGs and Jagdpanthers to finish before I get back to the Sherman fleet so no rush right now.

Saturday, November 14, 2020

World War II Project - Jagdpanthers - Priming

More action at the airbrush booth saw all three Jagdpanthers get coats of both black and grey primer. Like the STuGs the lower hulls were done in black and the upper hulls were done in grey. I had a little speckling going on so I may have to go back with some steel wool and remove the imperfections in the primer. I was pretty pleased with how well the thread I used for the tow cables looks with just a bit of primer on it. I think that's going to look really good by the end of the painting process. I was tempted to use my Vallejo primers on these just to compare the Vallejo vs Badger's Stynylrez primer, but once I have painted loaded up in the airbrush I tend to just keep going with what's in it.

Thursday, November 12, 2020

World War II Project - STuGs - Painting Begins

Finally managed to get over to the airbrush booth and applied some spot primer to the STuGs. I basically primed the debris shields and the backs of the skirts where I had bent the top edge. I also reprimed the lower hulls with black, hopefully to help keep those areas a bit darker. I used my favorite grey and black Stynylrez Primers from Badger for this work.

Wednesday, November 11, 2020

Tuesday, November 10, 2020

World War II Project - Jagdpanther Mods - Brackets and Tow Cables

It was a good weekend, along with finishing off the STuG modifications I was also able to finish off the Jagdpanther mods. I was originally trying to cut the brackets from little square pieces of styrene sheet. This was not going well. I then ran across some styrene angle stock and cut the rest of the brackets from that. They aren't as consistent looking as I would like but I figure with a little paint folks aren't likely to notice. The tow cables are made from the cable ends provided in the get and some black thread. I have no idea where the black thread came from but its braided and is just about the perfect diameter.

It was certainly a struggle to get everything to fit nicely and the cable to bend a bit but I sure like how it looks on the Jagdpanthers. I'll definitely keep using this thread for cables (I used it on the M32B1 as well) and looking at the spool I probably have a lifetime supply.

|

| Tow cables ready to go |

|

| The G2 ready for brackets |

|

| Brackets on the other side |

|

| Three Jagdpanthers ready for tow cables |

|

| A little straighter than I wanted on my first attempt. |

|

| This might be to much on the other side. |

|

| Tow cables complete |

|

| Ready for the airbrush booth. |

Monday, November 9, 2020

World War II Project - STuG Mods - Debris Shield Finished

|

| Long pieces of styrene rod in place, these get trimmed down after the glue has set |

|

| After trimming |

|

| Three STuGs and one STuH after mods |

|

| Ready for the airbrush booth...finally |

Wednesday, November 4, 2020

Thursday, October 29, 2020

World War II Project - Back to the Stug - Debris Shield II

Progress has been made. I filed down the plastic that I used for the first debris shield and it looks much better although I think it sits a little to high, but I'm actually not going to worry about it. Since its a field modification there is definitely going to be some distinct difference between one vehicle and the next. I also added some strip styrene in the gap to add some strength and serve as the beginning of the weld seam. I wanted to add some rod styrene but what I had was to big and I resorted to using the .010 x .020 strip.

|

| Unfortunately it just seems to be really hard to capture what the edge looks like now. |

After going through this and snapping off at least three "legs" trying to recreate it. I decided that I needed a different approach. Instead of using the .030 (which is to thick visually anyway) I decided to use two pieces of .010. This way I could cut through the top piece (carefully) and the bottom piece would still hold everything together. This .010 sheet is very flexible and it worked like a charm to build the other three debris shields.

I was finally to the easy part. I glued the three shields in place, dropped in the strip styrene to fill the gap and started trimming it to fit. Once it has dried solidly I'll apply some liquid cement to the "weld" and as the plastic softens from the glue work it with a knife to resemble a weld. After that I'll add a couple of bolt heads to each side and the STuGs will finally be ready for paint...again.

|

| Glue them in place |

|

| Fill the gap |

|

| Starting to trim. The high part of the strip will get trimmed up after it has dried solidly. Thank goodness for sharp clippers. |